German ZEISS CONTURA

three-dimensional measuring equipment

Productivity and efficiency are taken to new heights. Because measurement results are more reliable, your products will be more trustworthy. Newly upgraded to more reliable measurement results.

Quality Three-Nos Policy

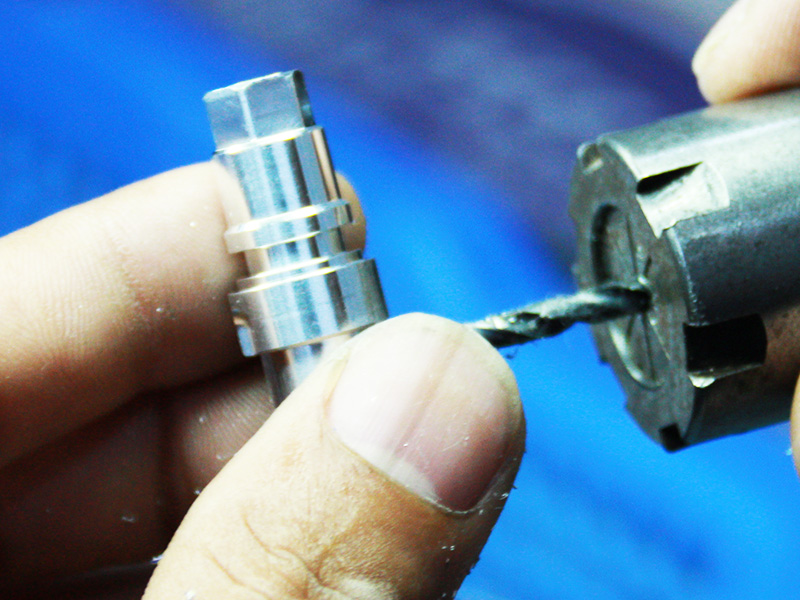

Do not manufacture defective products

This is what every on-site personnel must first ensure. Only by not producing defective products can it be possible not to leak out or accept defective products.

Do not flow out defective products

Once an operator discovers a defective product, he must stop the machine in time, cut off the defective product in this process, and complete the disposal and establishment of recurrence prevention countermeasures within this process.

Do not receive defective products

Once the post-process personnel find a defect, they will immediately shut down the process and notify the previous process. The front-process personnel immediately stopped processing, investigated the cause, and took countermeasures.

High precision inspection equipment

Mitutoyo contour measuring machine

CNC 2.5D Optical image measuring instrument

CNC 2.5D Optical image measuring instrument

2.5D Non-Contact Video Measuring System (Arcs)

Surface Roughness Tester (Mitutoyo SJ-410)

Image Dimension Measuring System (Keyence)

Digital Hardness Tester

Depth Gauge Height Gauge (Mitutoyo)

KDAE team’s spiritual philosophy

Implement every current work and gradually achieve short-term goals, with the goal of completing long-term strategic plans in a practical manner. In our daily work, we implement the policy of sustainable management at all times.

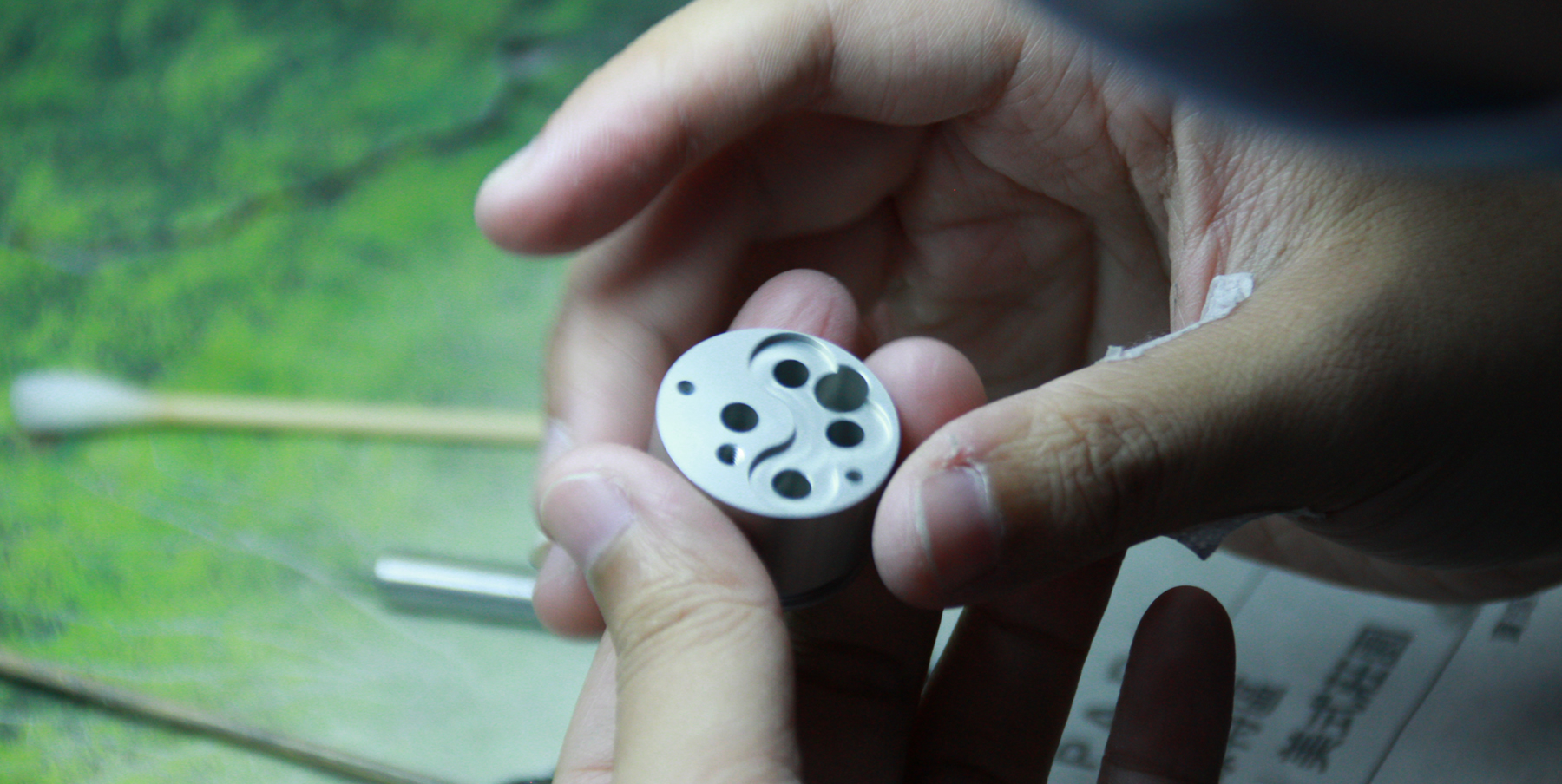

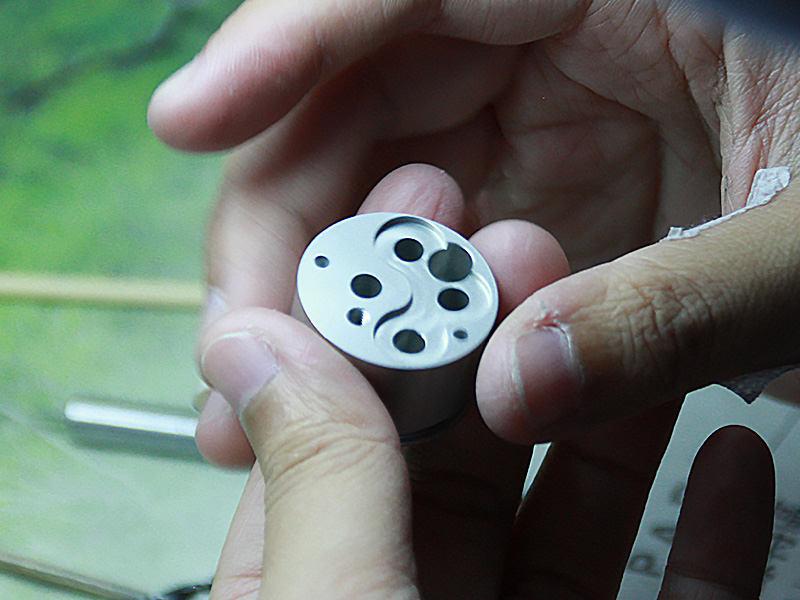

quality control

We have strict quality control procedures

Our quality control team is professionally trained and has many years of experience in the field of quality control. Our quality control goal is: to deliver good products from the factory and not to produce defective products.